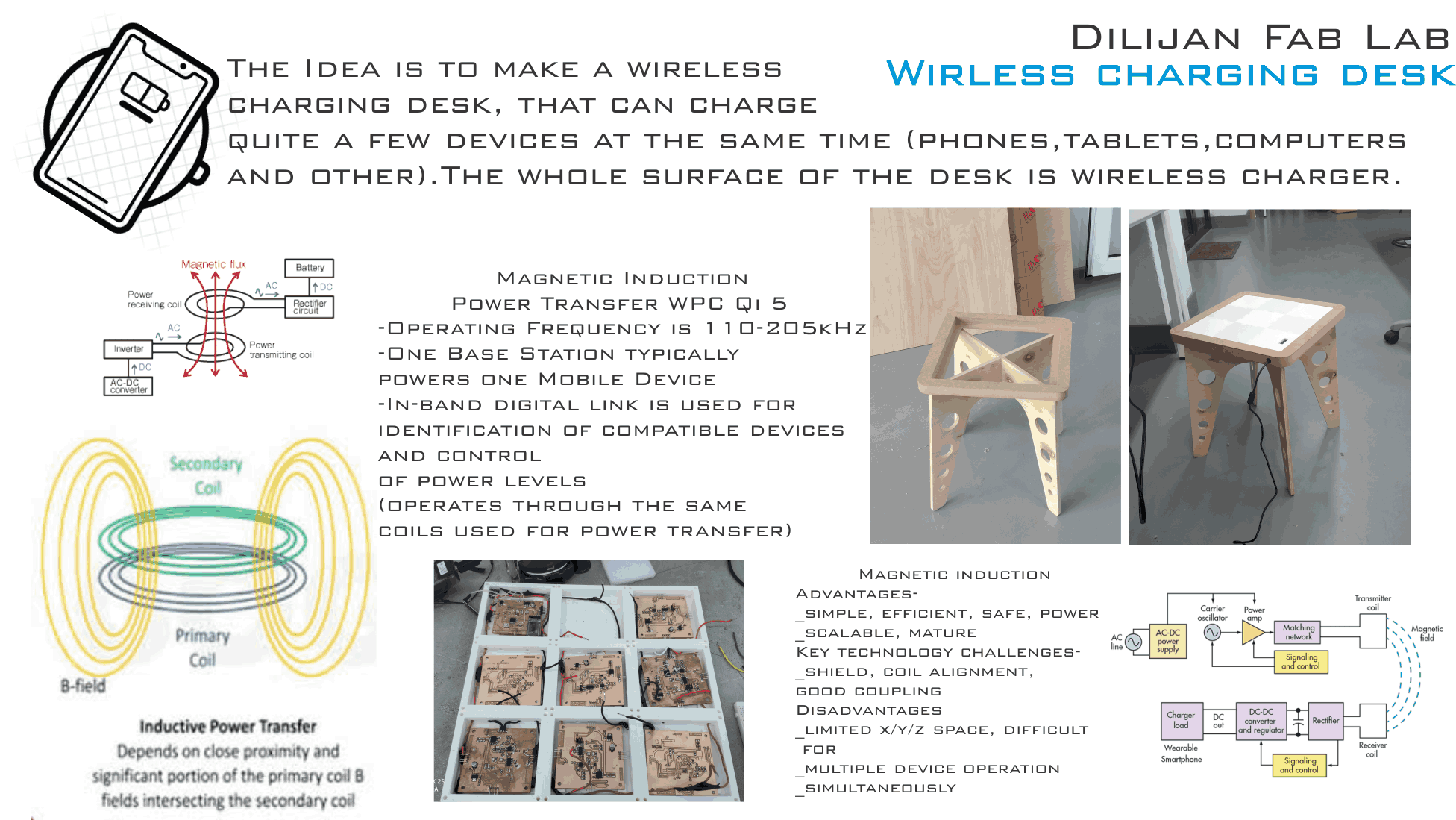

Final Project / Fab Wireless Charging desk

Requirments for final project and learning outcomes

What does it do?

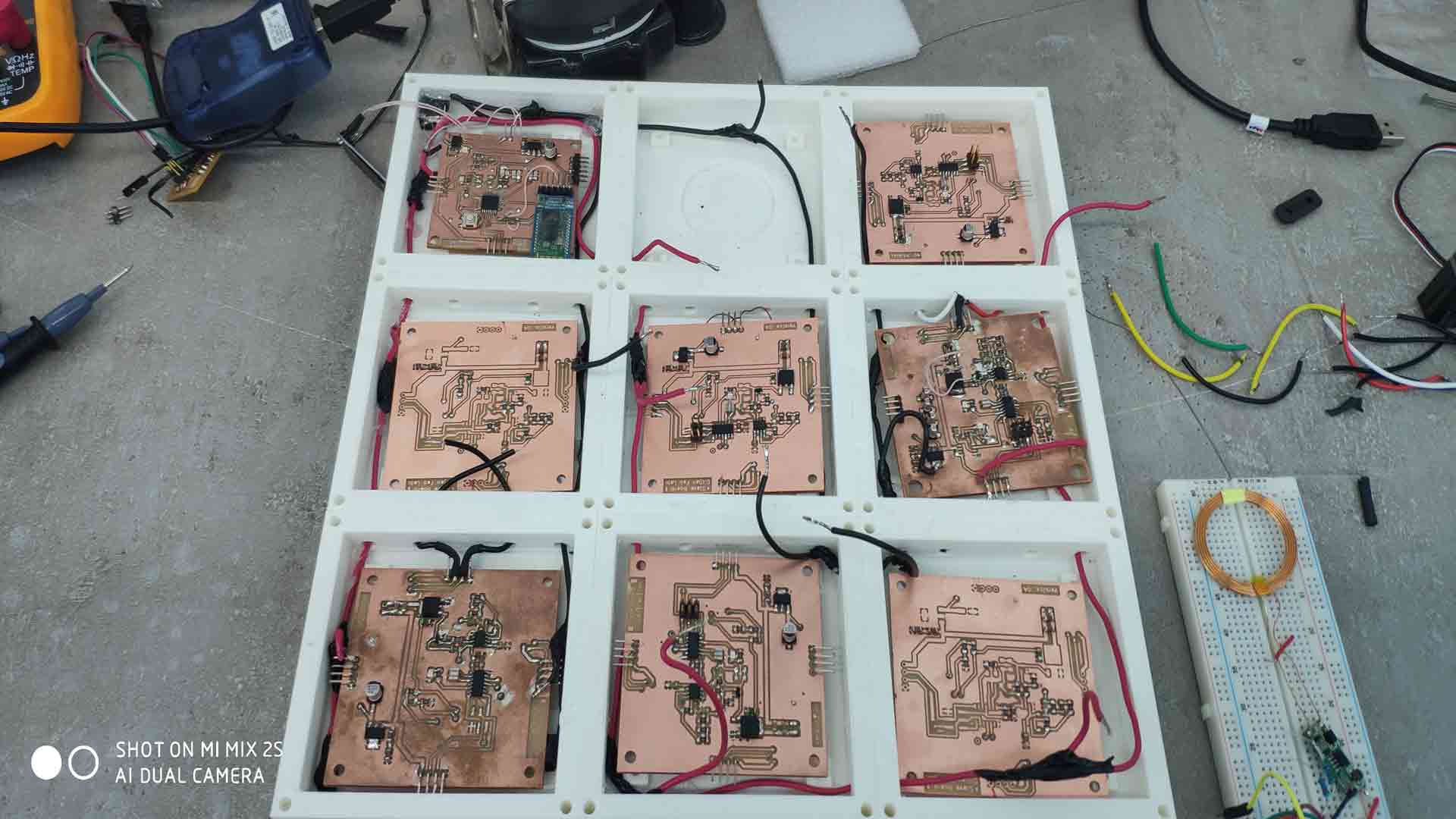

Wireless Charging desk is a charger for phones and computers, it charges devices wirelessly. It can charge a few devices at the same time(8 phones, or 1 computer). Also, it takes data(Temperature, and Power) from each charging coil and sends data about the status of the charging coil wirelessly (Bluetooth HC-05)

Who's done what beforehand?

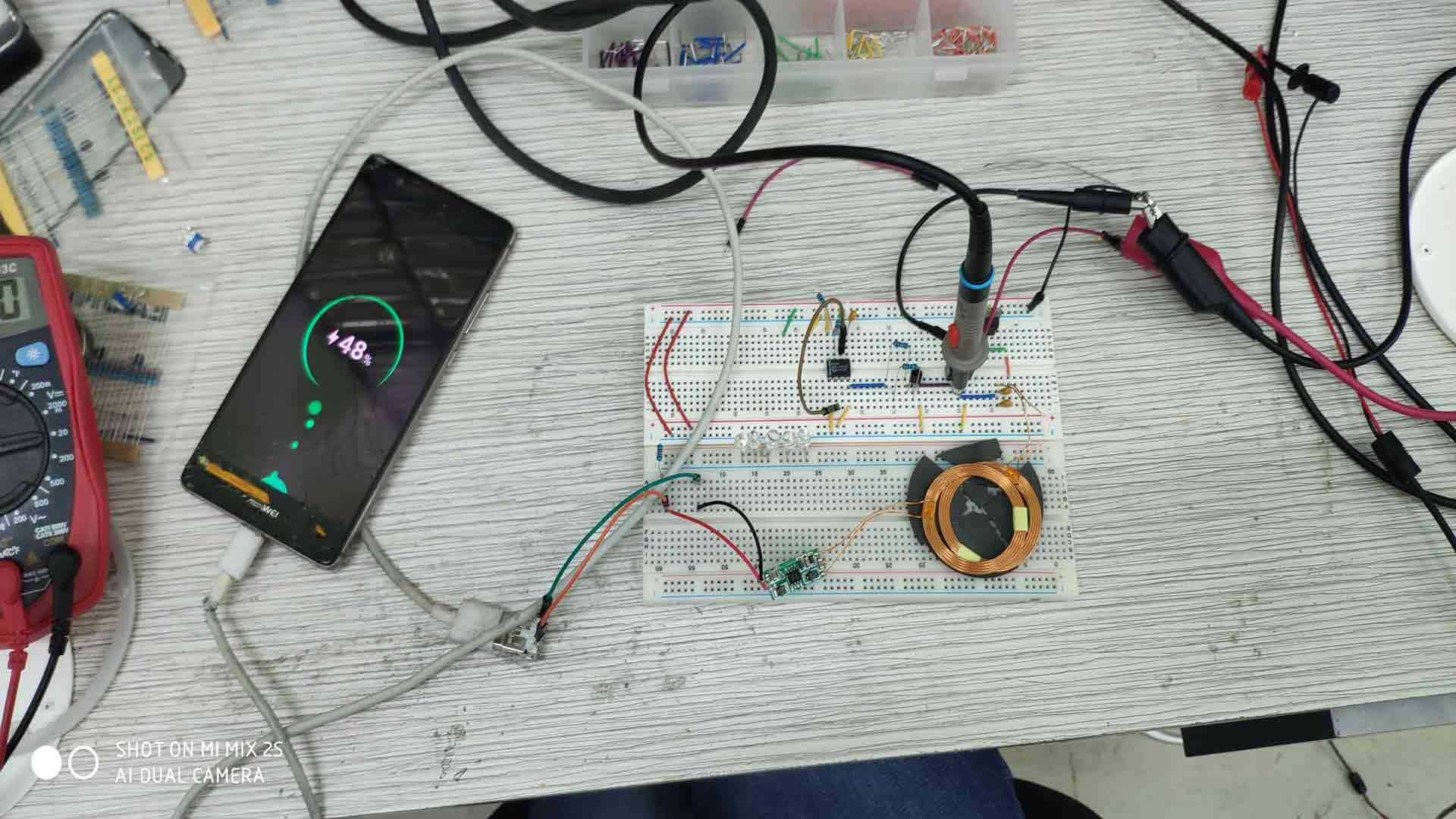

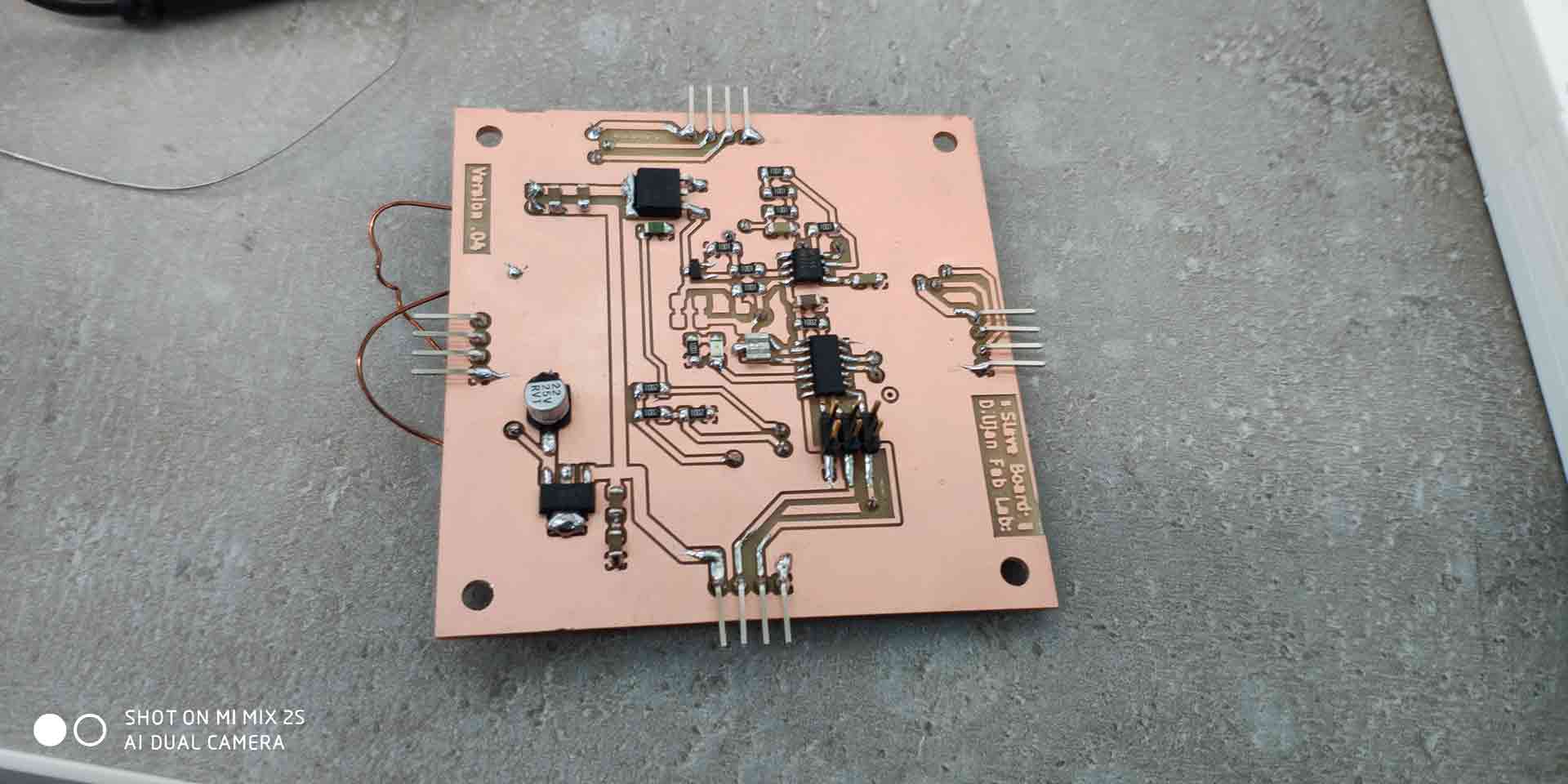

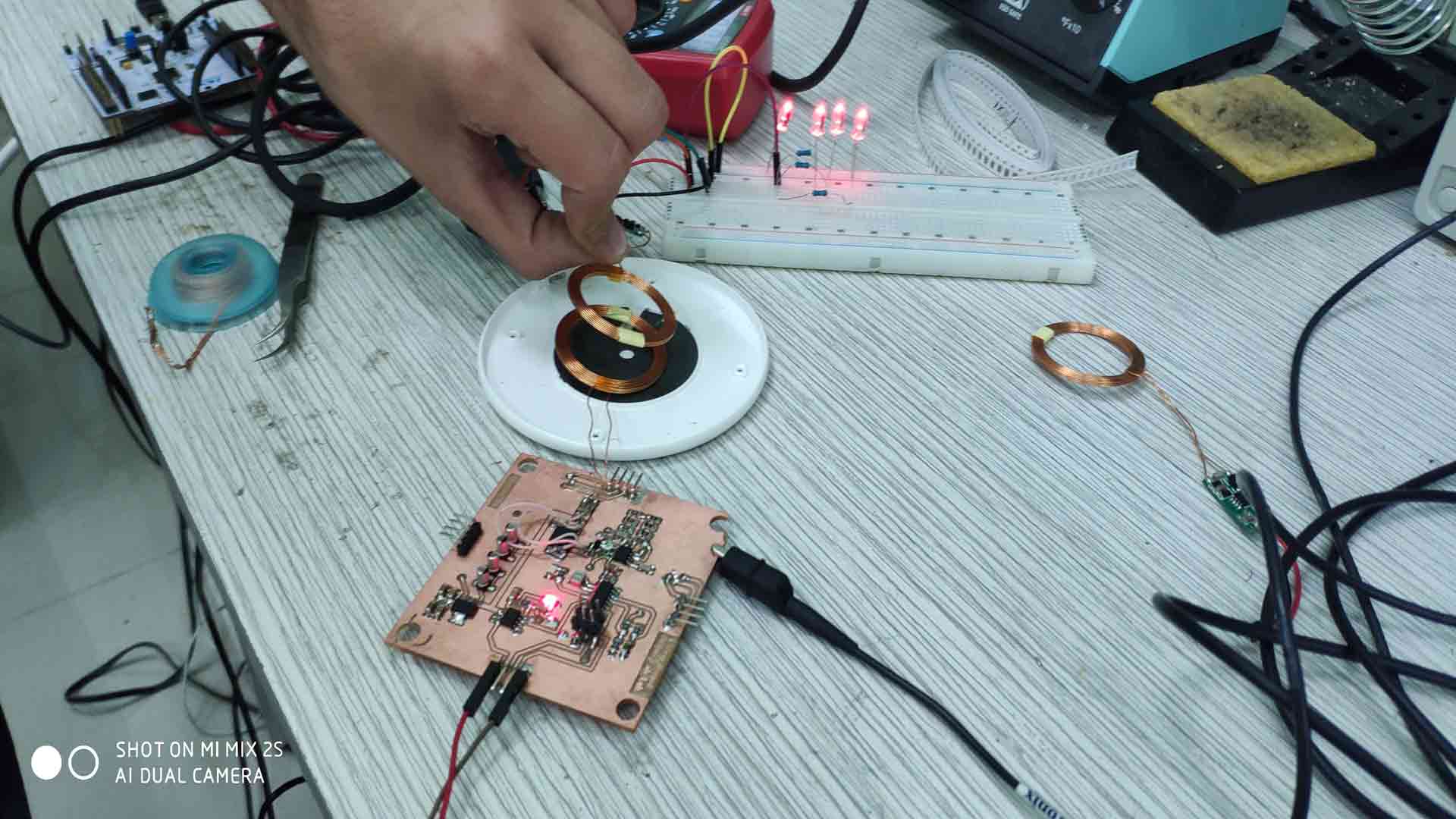

Wireless Charging desk has two main boards, master and slaves(1master, 8 slaves ). Slave board is charger board it has high-frequency circuit on it, coil, microcontroller (attiny44a), and a temperature sensor which measures MOSFET temperature. Master board is connected to all salve boards by I2C serial communication bus, it’s receives data from slaves(temperature) and sends it by Bulootuth module (HC-05), also it’s right info on OLED display(Monochrome 0.96" 128x64 OLED graphic display).

What did you design?

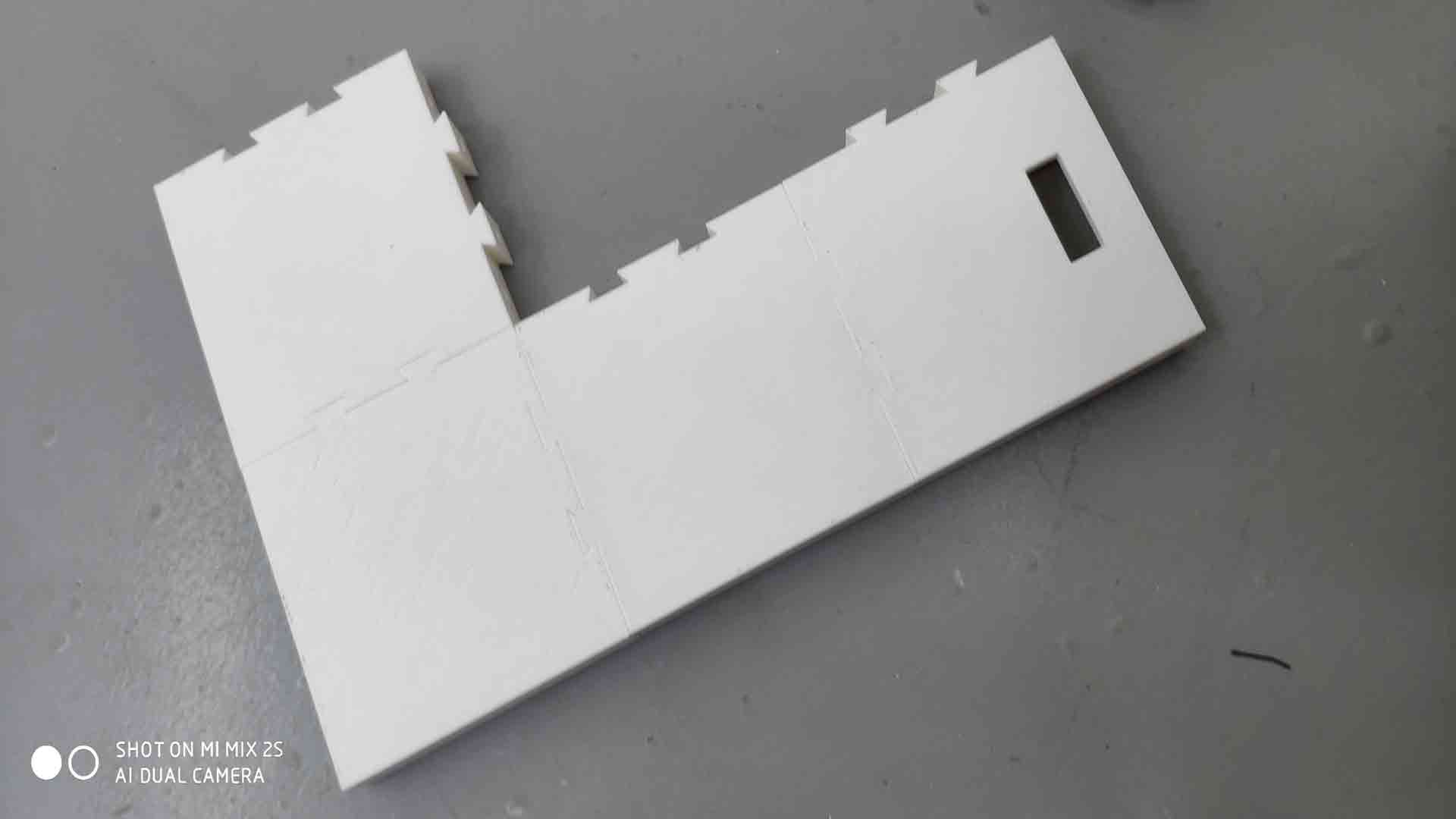

I have a design 3D model of boxes for master and slave boards by using Autodesk Inventor. I what it to be like a snap kit (and also I can use them separately). I have a design 3D model of frame for 3D model boxes to fit in. Also, I have the boards (Master and Slave ) using KICad, and I have simulated my board high-frequency circuits on lt spice.

What materials and components were used?

I have used

Where did they come from?

Mostly parts I get from the lab, only I have to buy HC-05 Bluetooth module, OLED graphic display, Copper wires, and ACS712 current measuring sensor. I want to buy ST controllers for charging(It would be easier for me) but tried to use what I have in the lab.

How much did they cost?

Total cost for materials and components is about ~ 70 $

What processes were used?

High-frequency generator with amplification using 555 timers, N chanal MOSFET, and NPN transistor which gives output to the coil. I2C communication, Bluetooth communication, ADC reading for the temperature sensor, current measuring sensor.

Files

Which tools I use for this project .

CAD Design

- Fusion 360

- Autodesk Inventor pro 2018

- Coral draw 2017

3D Printers

- Makerbot replicator 2

- Ultimaker 2 extended plus

- Shindoh 3Dwox

Laser cuters and CNC machines

- Epilog mini laser cuter

- Shop bot CNC machine

Electronics

- Roland SRM-20

- Soldering iron Weller WES51

- SMD electronic componetes(res.,cap. ,and other)

- AVR programmer

Project Details:

Project Development:

Slide